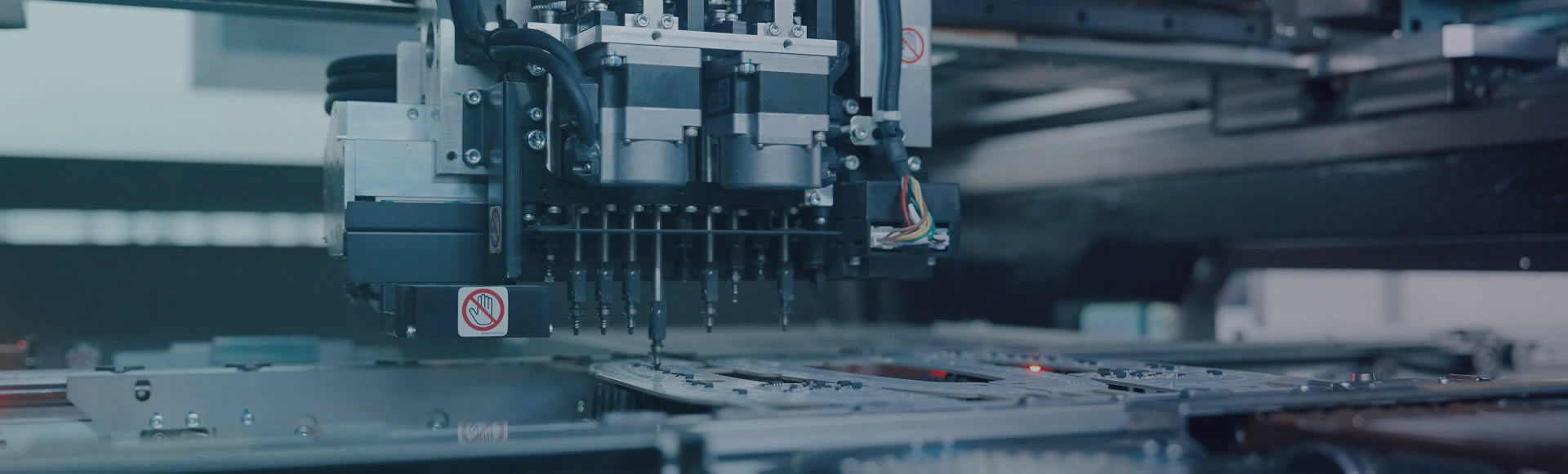

The production processes cover the entire manufacturing cycle, including automated marking, SMT mount, soldering, coating, testing and product assembly. All processes incorporate error-proofing design and full product traceability throughout the production flow.

Component mount capabilities: Support components ranging from 01005 (0.4mm x 0.2mm) to large components (connectors, BGAs, etc.); capable of handling all types including resistors, capacitors, inductors, ICs, BGAs, QFNs, POP (Package on Package), etc.

Mount Specifications: with a maximum speed of 8,4000 cph*1 ( IPC9850 ( 1608 ) : 61 200 cph*1 ) ; with a placement accuracy of ±40 μm.

Board size capacity: supports large substrates up to 750 × 550 mm.

Vacuum reflow soldering: capable of challenging soldering processes for complex components (BGAs, QFNs, LEDs, etc.); void rate controlled to 5%-10% (significantly below IPC-610 Class 3 standards).

These production line are characterized by high precision, high speed, exceptional flexibility, and superior reliability, capable of meeting manufacturing requirements for consumer electronics, automotive electronics, and industrial control products.